0

0 EUR

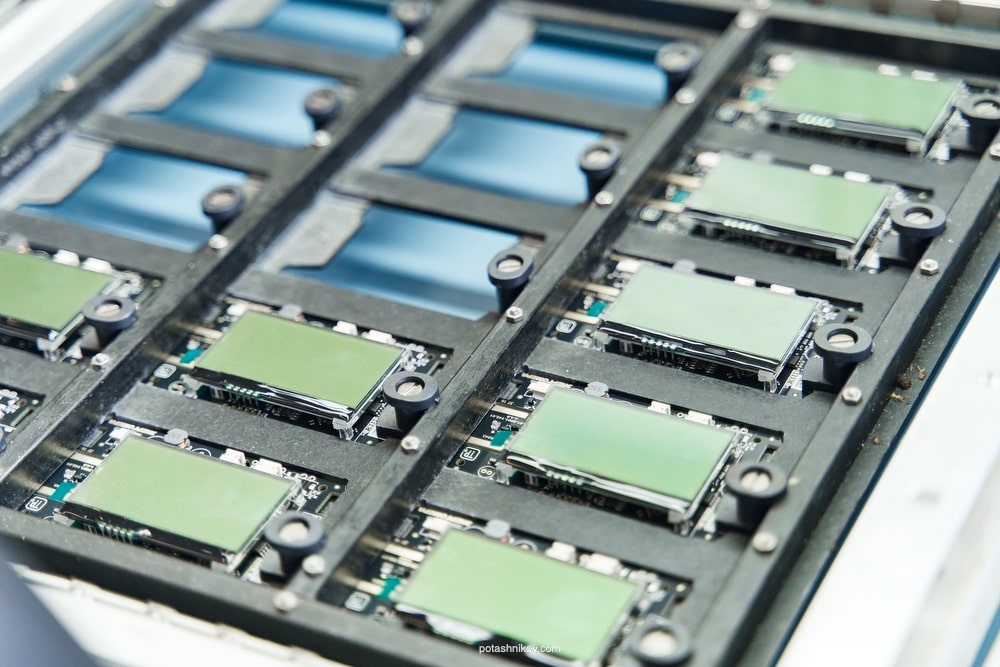

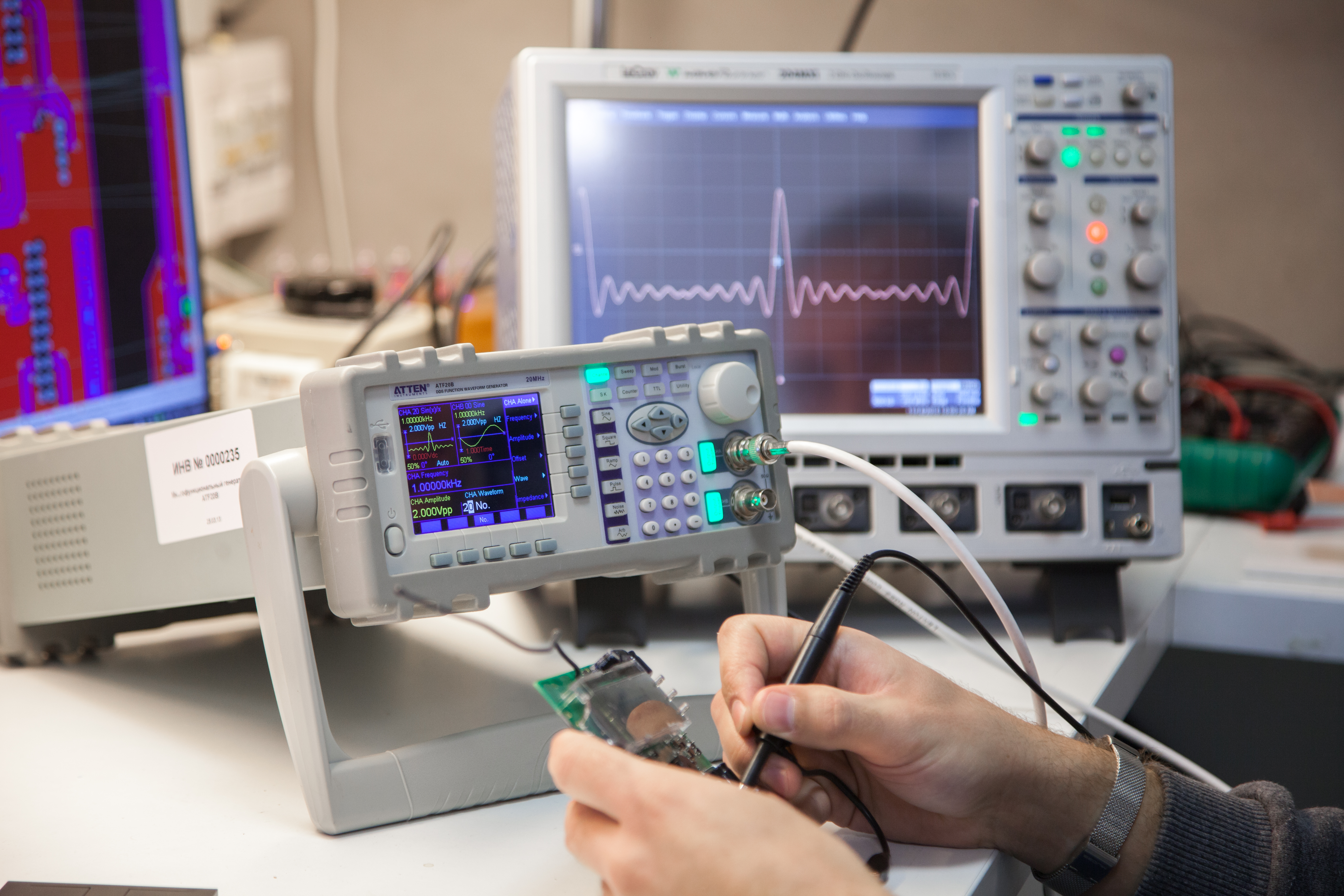

- Technological processes are carried out on modern equipment

- 25 years of experience in the production of electronic devices

- Low cost of components and packaging due to the large production volume

- 100% multi-stage automated quality control, valid ESD control program

- We accompany projects at all stages, provide engineering support

Advantages

Production of prototypes

Possibility of production of prototypes and trial batch of products

Project support

Engineering support at all stages and individual project support

Factory tour

Opportunity to visit production to communicate with technologists

Selection of components

Selection of components according to technical and economic requirements

Documentation check

Checking the correctness of the incoming design documentation at the stage of calculating the cost of the project

Order processing

Guaranteed fast calculation and order processing

Cost calculation

Send us a request for calculation, and we will contact you within a working day.

For a faster and more accurate calculation, we recommend that you indicate the number of required products when sending, as well as attach files:

- Specification (list of elements) in the form of a table;

- PCB design: PCAD / Gerber / Altium;

- Wiring diagram / assembly drawing: PDF, JPEG or BMP;

Request processing takes no more than two business days.

For a faster and more accurate calculation, we recommend that you indicate the number of required products when sending, as well as attach files:

- Specification (list of elements) in the form of a table;

- PCB design: PCAD / Gerber / Altium;

- Wiring diagram / assembly drawing: PDF, JPEG or BMP;

Request processing takes no more than two business days.